Optical Leak Testing is an advanced leak test technology incorporating a sensitive full field interferometer that allows the user to inspect for gross and fine leaks simultaneously. The technique eliminates the long pressure bombing and the gas absorption issues typical of Helium Mass Spectroscopy and Krypton 85. OLT also eliminates the problems associated with gross leak testing using fluorocarbons or red dyes.

Tech Info

Advantages of OLT

- Inspects for both gross and fine leaks simultaneously (Model 2020)

- Eliminates bubble leak testing for gross leaks, and the use of fluorocarbons

- Eliminates red dyes used with Kr85 gross leak testing

- No helium bombing required

- Easily run by unskilled operators

- Accommodates “welding trays” from typical seam welders

- Immediate feedback for welding related issues; the test results can be networked for immediate Statistical Process Control

- Not susceptible to gas absorption like Helium Mass Spectroscopy or Krypton 85 testing

- Can inspect up to 1000 devices simultaneously (Model 2020 WL)

- Can inspect board mounted devices (Model 2020)

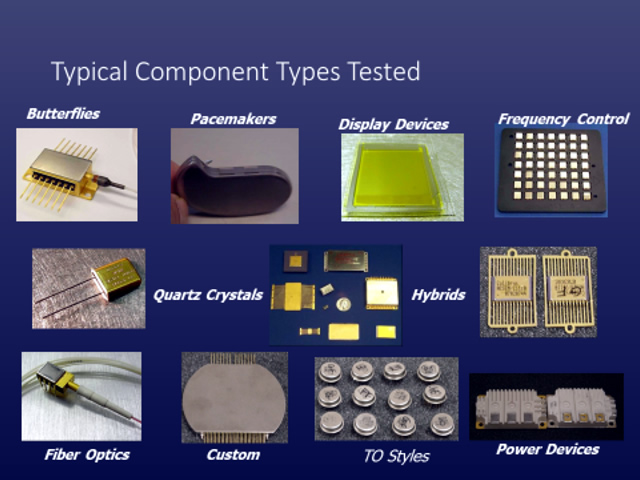

Example Devices

- Butterflies

- Pacemakers

- Display Devices

- Frequency Control

- Quartz Crystals

- Hybrids

- Fiber Optics

- TO Styles

- Power Devices

- Custom

Request a device sample test or follow-up call:

NorCom can inspect your sample devices with OLT and furnish a full leak test report at no cost.

HOW OLT WORKS

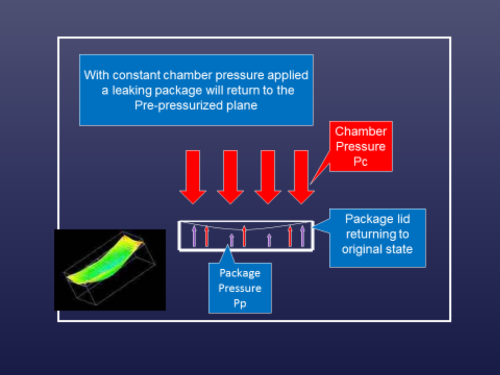

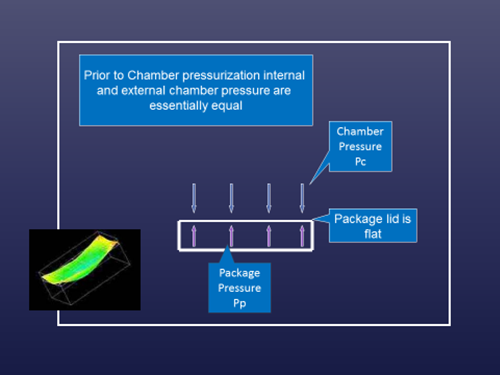

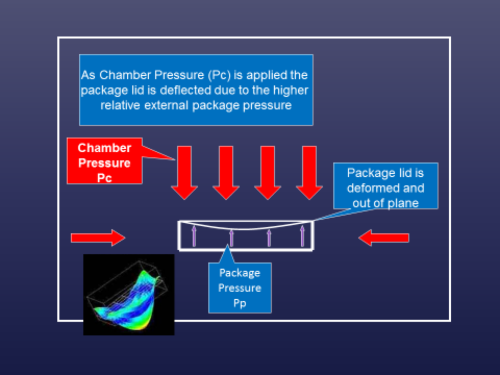

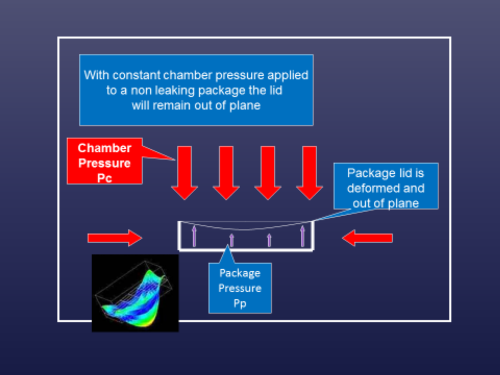

The Optical Leak Test (OLT) system inspects sealed electronic devices by measuring the lid deflection of the package over time with a holographic interferometer while the device is under a controlled pressure. The lids of all the devices under test are imaged simultaneously by the holographic camera and processed by the NorCom proprietary imaging software.

Prior to pressurization the package lid is flat.

Once the chamber is pressurized, the package lid will deflect very slightly, and the resultant deformation is measured in microns/psi.

A device that is hermetic will stay deflected under pressure

The lids of leaking packages will either not move (gross leak), or will move back towards their original state (fine leak). The change in internal pressure of the package is then reported in cc atm/sec of the test gas, and the leaking parts are automatically rejected.